MÁY ÉP BÙN BĂNG TẢI TEFSA

-

Model:BELT FILTER PRESS

-

Thương Hiệu:TEFSA

-

Xuất xứ:TÂY BAN NHA

Liên hệ hotline 0918 072 181 để được tư vấn

DANH MỤC SẢN PHẨM: MÁY ÉP BÙN BĂNG TẢI

MÁY ÉP BÙN BĂNG TẢI

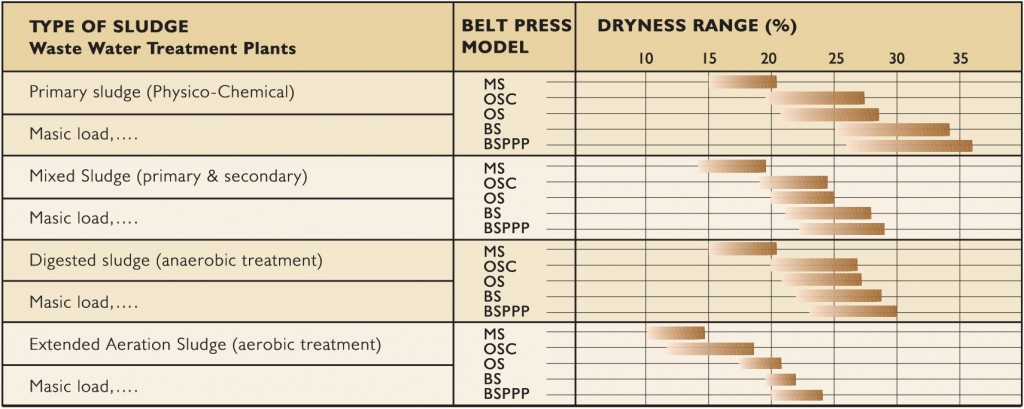

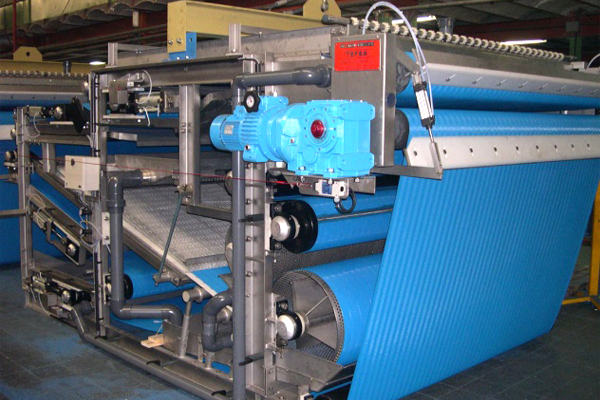

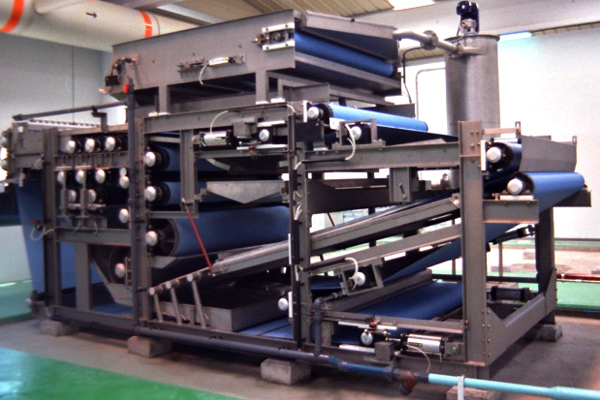

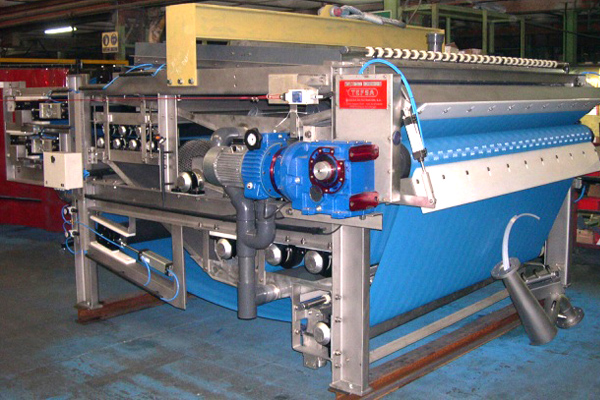

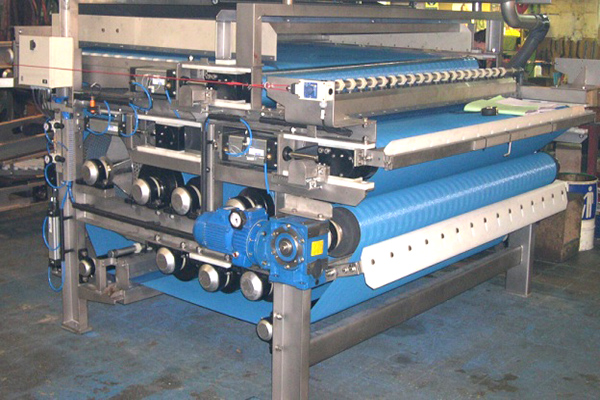

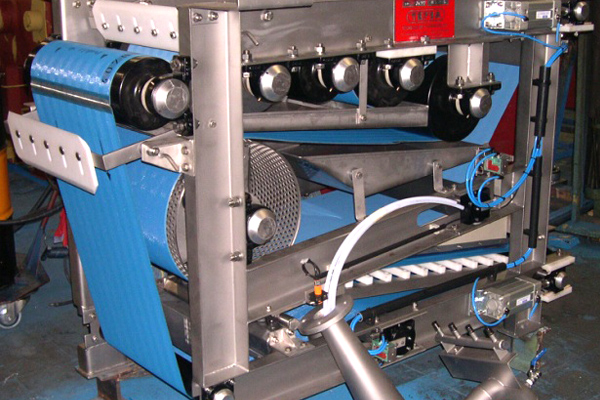

Máy ép bùn băng tải TEFSA được chế tạo bằng các vật liệu đặc biệt với khung máy ép bùn được làm bằng Inox 304 nên có thể làm việc trong môi trường có độ ăn mòn hóa học cũng như cơ học cao. Máy ép bùn băng tải TEFSA được trang bị băng tải cô đặc bùn trước ép, thiết kế băng tải ép đa tầng giúp tiết kiệm diện tích lắp đặt, cùng hệ thống cân chỉnh băng tải tự động bằng khí nén. Máy ép bùn băng tải hoạt động tự động và liên tục, bùn sau ép đạt độ khô cao. Máy ép bùn có dãy công suất rộng, chiều rộng băng tải từ 0.5 – 3 m và công suất xử lý lên đến 35m3/h (tính theo nồng độ bùn là 3%).

TÁCH NƯỚC BÙN THẢI BẰNG MÁY ÉP BÙN BĂNG TẢI TEFSA

Tách nước bùn thải là gì ?

Bùn thải phát sinh ở giai đoạn cuối của các hệ thống xử lý nước thải, dạng huyền phù có hàm lượng nước rất cao và nồng độ chất rắn thấp từ 1-3% nên việc xử lý bùn thải ở các bước tiếp theo rất tốn kém. Do đó tách nước bùn thải là điều rất cần thiết. Tách nước bùn thải là quá trình làm giảm thể tích và khối lượng bùn đến mức thấp nhất có thể bằng các biện pháp cơ học hoặc thủ công.

Vì sao cần phải tách nước bùn thải ?

Chi phí vận chuyển và xử lý bùn thải được tính toán dựa trên khối lượng bùn. Việc tách nước bùn thải có thể làm thể tích và khối lượng bùn xuống 10 lần điều đó đồng nghĩa chi phí mà quý công ty thuê các đơn vị thu gom và xử lý bùn thải cũng sẽ giảm xuống 10 lần tương ứng.

NGUYÊN TẮC HOẠT ĐỘNG CỦA MÁY ÉP BÙN BĂNG TẢI TEFSA

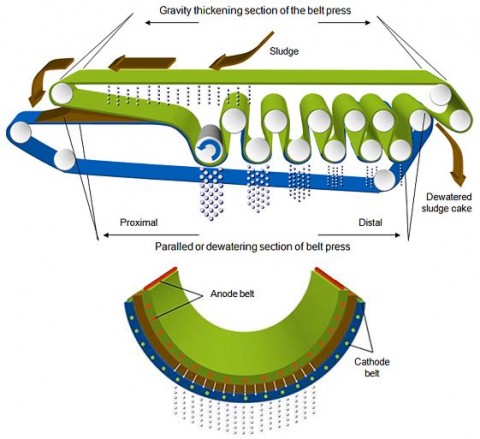

Bùn loãng được keo tụ, tạo bông nhằm cải thiện khả năng tách nước trước khi đưa vào máy ép bùn băng tải TEFSA. Bùn sau khi keo tụ được bơm bùn vận chuyến đến băng tải phụ của máy. Tại đây, bùn được được phân bố đều trên băng tải và dưới tác dụng của trọng lực bùn sẽ được tách nước sơ bộ và nồng độ bùn rắn tăng từ 1 đến 3%. Chiều dài của băng tải phụ từ 1-2m tùy theo thiết kế.

Tiếp theo, bùn được kẹp giữa hai băng tải và được tạo lực nén ép bằng hệ thống rulo quay quanh trục. Nước sẽ được loại dần khi băng tải lần lượt đi qua vùng nén ép áp thấp đến vùng nén ép áp cao (Áp suất nén ép tùy thuộc vào đường kính và mật độ và cách bố trí của các rulo). Đến cuối quá trình nén, bùn đạt độ khô cao với nồng độ chất rắn >25% và thể tích bùn giảm > 10 lần.

Bã sau ép được tách khỏi băng tải bằng hệ thống dao cạo bùn được thiết kế phía cuối máy và được rửa sạch bằng hệ thống ống vòi phun cao áp để tiếp tục quá trình tách lọc. Máy ép bùn băng tải chạy tự động và liên tục với hệ thống cân chỉnh băng tải tự động bằng khí nén.

CÁC DÒNG SẢN PHẨM BĂNG TẢI TEFSA

|

|

|

|

|

MÁY ÉP BÙN MODEL BĂNG TẢI BS |

MÁY ÉP BÙN BĂNG TẢI MODEL BSPP |

MÁY ÉP BÙN BĂNG TẢI MODEL OS |

|

Máy ép bùn băng tải model BS được hoàn thiện toàn diện, đạt công suất xử lý lớn và đem lại hiệu quả tách lọc cao. Máy ép bùn được làm bằng vật liệu đặc biệt để phù hợp với nhiều ứng dụng khác nhau. Sự kết hợp hoàn hảo giữa băng tải tách nước bằng trọng lực (gravity belt press) và băng tải chính giúp máy có thể đáp ứng được các yêu cầu công nghệ khắt khe nhất. Chiều dài băng tải của Model BS từ 0.5 – 3 m và công suất xử lý của máy từ 2 – 35m3/h. |

Máy ép bùn băng tải model BSPP có vật liệu cấu tạo và đặc tính tương tự như Model BS. Điểm khác biệt là diện tích lọc của máy ép bùn được tăng thêm 20% bằng cách tăng chiều dài của băng tải chính và thiết kế thêm 6 rulo gia áp trước khu vực tháo bánh. Do đó, bùn được vắt nước triệt để và bánh bùn đạt được độ khô cao. Chiều dài băng tải của Model BS từ 1.5 – 3 mét và công suất xử lý của máy từ 10 – 35 m3/h. |

Máy ép bùn băng tải model OS được phát triển để chuyên xử lý bùn vô cô cơ trong các khu công nghiệp, máy có áp suất nén trung bình và ít rulo tăng áp hơn so với các model BS và BSPP. Chiều dài băng tải của Model BS từ 0.5 – 3 mét và công suất xử lý của máy từ 2 – 30 m3/h. |

|

|

|

|

|

MÁY ÉP BÙN BĂNG TẢI MODEL OSC |

MÁY ÉP BÙN BĂNG TẢI MODEL MS |

BĂNG TẢI PHỤ PDH |

|

Máy ép bùn băng tải model OSC đảm bảo 3 yêu cầu: công suất xử lý nhỏ, thiết kế nhỏ gọn để tiết kiệm không gian lắp đặt và đem lại hiệu quả tách lọc cao với chi phí đầu tư thấp. Chiều dài băng tải của Model BS từ 0.5 – 2 mét và công suất xử lý của máy từ 2 – 15 m3/h. |

Máy ép bùn băng tải model MS được áp dụng cho các hệ thống xử lý có công suất nhỏ hoặc hoặc những dự án yêu cầu máy ép được thiết kế di động. Máy hoạt động ở áp suất nén thấp với chiều rộng băng tải từ 0.5-1 m và công suất xử lý từ 1-10 m3/h |

Băng tải phụ được thiết kế độc lập với máy ép bùn băng tải TEFSA và được lắp phía trên máy. Băng tải phụ được sử dụng để cô đặc bùn trước khi được đưa vào băng tải chính khi nồng độ bùn đầu vào quá thấp. Thiết bị được trang bị hệ thống cân chỉnh băng tải tự động bằng khí nén và vòi rửa cao áp. Chiều rộng băng tải từ 0.5-3 m và chiều dài băng tải từ 1-6m với công suất cô đặc bùn từ 2-150m3/h. |

TẠI SAO LẠI SỬ DỤNG MÁY ÉP BÙN BĂNG TẢI TEFSA

-

Máy ép bùn băng tải TEFSA hoạt động tự động và liên tục, không cần người đứng máy

-

Chi phí đầu tư, vận hành và bảo dưỡng máy ép bùn băng tải TEFSA thấp

-

Tiết kiệm điện năng do sử dụng motor hiệu năng cao và công suất tiêu thụ điện thấp.

-

Dãy công suất rộng đáp ứng mọi công suất của dự án thuộc mọi lĩnh vực khác nhau

-

Máy có thiết kế nhỏ gọn và sử dụng vật liệu chất lượng cao nên tiết kiệm diện tích lắp đặt mà vẩn đảm bảo công suất xử lý thiết kế